- Australia / AUD $

- Canada / CAD $

- China / CNY ¥

- France / EUR €

- Germany / EUR €

- Hong Kong SAR China / HKD $

- Ireland / EUR €

- Italy / EUR €

- Japan / YEN ¥

- Kuwait / USD $

- Macao SAR China / HKD $

- Netherlands / EUR €

- Qatar / USD $

- Saudi Arabia / USD $

- Singapore / SGD $

- South Korea / KRW ₩

- Spain / EUR €

- Taiwan / TWD $

- United Arab Emirates / USD $

- United Kingdom / GBP £

- United States / USD $

- Not yours? Read more

Tell us what you think

Shop in your local currency and language

You are currently in Kuwait KW / USD $ store

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

- English

Did you know that we deliver to 130 countries or regions and offer a range of delivery options to suit you wherever you are in the world? Find out more

Sign up once to our Selfridges+ service and you can enjoy unlimited deliveries wherever you are in the world. FIND OUT MORE

International delivery

With almost everything on selfridges.com available for International Delivery, you can send your order to 130 countries or regions around the world, including North America, Australia, the Middle East and China.

Although we only offer 20 currencies to browse in online, you can still deliver to all of the following countries or regions:

- Algeria

- Andorra

- Antigua and Barbuda

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Bermuda

- Bolivia

- Botswana

- Brunei

- Bulgaria

- Cambodia

- Canada

- Cayman Islands

- Chile

- China

- Colombia

- Costa Rica

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Dominica

- Dominican Republic

- Ecuador

- Egypt

- El Salvador

- Estonia

- Finland

- France

- French Guiana

- Germany

- Gibraltar

- Greece

- Grenada

- Guadeloupe

- Guatemala

- Guernsey

- Guyana

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Ireland

- Israel

- Italy

- Jamaica

- Japan

- Jersey

- Jordan

- Kazakhstan

- Kenya

- Kuwait

- Laos

- Latvia

- Lebanon

- Lesotho

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Malaysia

- Maldives

- Malta

- Martinique

- Mayotte

- Mexico

- Monaco

- Montserrat

- Morocco

- Myanmar

- Namibia

- Netherlands

- New Zealand

- Nicaragua

- Nigeria

- Norway

- Oman

- Pakistan

- Panama

- Paraguay

- Peru

- Philippines

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Rwanda

- Saint Kitts and Nevis

- Saint Lucia

- Saint Martin (French part)

- San Marino

- Saudi Arabia

- Serbia

- Singapore

- Slovakia

- Slovenia

- South Africa

- South Korea

- Spain

- Sri Lanka

- Suriname

- Swaziland

- Sweden

- Switzerland

- Taiwan

- Tanzania

- Thailand

- Trinidad and Tobago

- Turkey

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- Uruguay

- Venezuela

- Vietnam

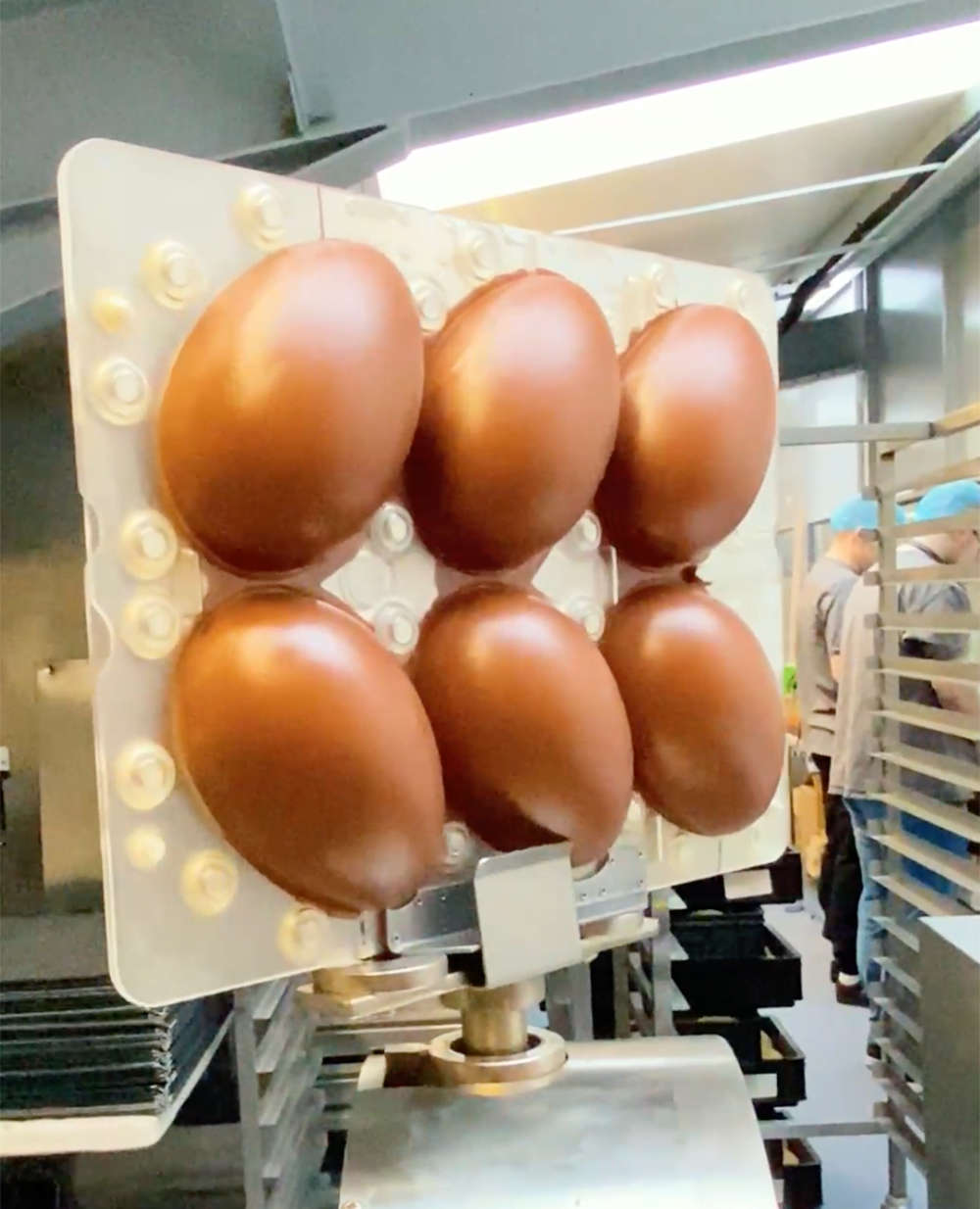

“Cocoa has more flavour compounds than any other foodstuffs in the world, which is absolutely amazing but really sad as that isn’t the chocolate that everyone knows. The mission with Chocolarder is to introduce people to what real chocolate is.”

Mike Longman – founder of Chocolarder

Shop Selfridges Easter eggs

Can you talk us through the process of creating your chocolate?

Mike: We want full control over everything that goes into our chocolate, so we make it from bean to bar. When cocoa beans come in, we put them through a basic standardised roast and add a standard amount of sugar to make a 70% dark chocolate. Then we taste it. Chocolate is like wine: it has these amazing nuances that change, depending on the farm, farmer, year, yield, even what day of the month it was made. The flavours can range from leather and oak wood to cherry and tobacco. We want those complexities, so we then work out what roast and sugar we’ll use to bring out those flavours. The process of making the chocolate then takes about 60 days. We roast the cocoa beans, take the shell off to get the cocoa nib, refine it, age it for 30 days, remelt it, temper it and then finally wrap it. That’s all stuff we do in house.

How were the Selfridges Easter eggs created?

Mike: Working with Selfridges to create this year’s Easter eggs was a really fun process. You know your customers, so you develop the flavour ideas and then we get to put our spin on it. We’re a company that is focussed on ethics and sustainability, so this year we rescued would-be-waste orange peel from local cafés to give the vegan egg its orange flavour.

How do you work to make your manufacturing process more sustainable?

James: We think carefully about how we get the beans over here – we often bring them over via sailboat. We also use vintage machinery wherever we can. We source it from all over the world to save them from a life of rust or ending up in landfill. We’ve got quite the museum here at Chocolarder. We’ve recently been restoring a vintage roaster. We found it in France; it had survived a fire in its previous factory where it used to roast hazelnuts. Had it not been for those residual hazelnut oils, it would have rusted beyond repair.

What’s your favourite part of making the chocolate?

Becca: The foiling! Everything we do is obviously quite brown. But when you see the glisten of the foil when they’re being wrapped up, it just brightens the place up. And seeing a massive pile of eggs is always fun – it just makes me want to go out and hide them all.

Why chocolate?

Becca: Chocolate is obviously the dream. Like, who wouldn't want to work with chocolate? When you’re a kid, if someone said you’d get to work in chocolate, you’d think you were dreaming.

Mike: Chocolate is a little bit of everything. It’s everything a geek like me enjoys. It’s amazing flavours, amazing people. It’s tinkering with machines. It’s science, it’s physics, it’s chemistry. At the end of it you get something that everyone thinks they know, but really they don’t until they try chocolate like ours.

SELFRIDGES CELEBRATES

Lovers, mothers, fathers, family and friends. Make life a little brighter with a Selfridges celebration.

Our latest stories

Get inspired

The stories to feed your imagination. The conversations to get you thinking. The ideas to brighten your day. Read, watch and listen, right here.